Elevate Battery Development with NOGAMI

From prototyping coin cells and laminate cells for electrode charge/discharge tests

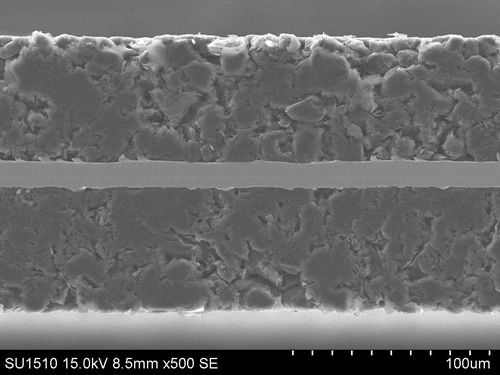

to preparing samples for SEM observation,

we address the challenges of battery development with our tools

that provide unparalleled processing quality.

REASONS

Why Battery Developers Worldwide Prefer NOGAMI

Unparalleled processing quality

Meeting the high-quality standards of battery development, we precision-process not only common positive and negative electrode materials but also challenging materials like silicon negatives.

High Usability

Our product design is driven by the on-site needs of battery development, such as the continuous processing of numerous samples for charge-discharge cycle testing, and/or operations within a glove box.

Durable and Long-lasting

Smooth sliding of the upper blade with no play, high rigidity that withstands long-term use.

High durability and a long lifespan, trusted by international users.

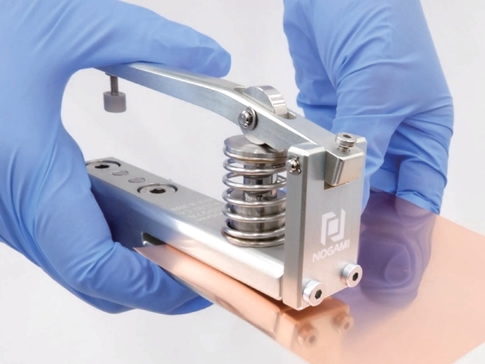

hANDHELD pUNCH

The de facto standard for secondary battery prototyping

Sales of 9,000 units worldwide Standard for precision

punching that continues to support secondary battery

development

NOGAMI Tools

Products

Featured Product

Desktop Precision Punching Jig

Clean Press

Handheld Electrode punch

[Φ1-26mm / □1-22mm]

Handheld Electrode punch for Quality Control

Desktop Precision Punching Jig Clean Press

Ultra Precision Punching Jig

for Cross-sectional observation

Cut Surface Finishing Jig

for Cross-sectional observation

Electrode Cutting Jig

[W150mm / W250mm]

REVIEW

User Testimonials

Frequently asked questions

FAQ

laboratory Service

世界各国から日々寄せられる様々な電池材料の精密加工と、より高度な打抜き/切断/塗工/測定などの技術革新に取り組んでいます。

無償試験

有償試験

ラボ利用

Pick UP “CP PRECUT for SEM”

全固体電池セルのノーダメージ加工

SEM用試料のCP・

イオンミリング前処理

全固体電池のフルセルなど、硬度や密着強度の異なる複数の材料が積層された複合材断面を、クラックや崩れ、層間の剥離なく超高品質加工。

硫化物系/ポリマー系固体電解質層、シリコン負極、リチウム金属負極、セラミックグリーンシートなど、多様な材料に対応。